Techniques for Effective Lapping of Gate Valves to Enhance Performance and Longevity

Understanding Gate Valve Lapping A Comprehensive Guide

Gate valves are essential components in various industrial applications, primarily used to control the flow of fluids. The effectiveness and longevity of these valves often depend on proper maintenance techniques, one of which is lapping. Lapping is a critical process that ensures the valve's sealing surfaces are perfectly flat and smooth, enabling effective sealing and minimizing leakage. This article delves into the concept of gate valve lapping, its significance, the lapping process, and the tools involved.

The Importance of Lapping in Gate Valves

Over time, gate valves can suffer from wear and tear due to constant use, exposure to corrosive materials, and fluctuating pressures. These factors can lead to damage on the sealing surfaces, which in turn results in leaks. Lapping the gate valve helps restore these surfaces to their original condition, ensuring that the valve can effectively seal and function as intended. Properly lapped valves can provide improved performance, reduce maintenance costs, and extend the overall lifespan of the valve.

The Lapping Process

Lapping is a precise machining operation that employs abrasives to achieve a smooth, flat surface on the sealing parts of a gate valve. The process usually involves several steps

1. Disassembly The gate valve must first be carefully disassembled to access the gate and seat surfaces. This step involves loosening bolts and taking apart various components without causing damage.

2. Inspection Before lapping, it is vital to inspect the sealing surfaces for any major defects. This includes checking for pitting, scratching, or any other signs of damage that might require repair or replacement.

gate valve lapping

3. Preparation After inspection, the surfaces must be cleaned thoroughly to remove any dirt, debris, or old sealant. Using a suitable cleaning agent ensures that all contaminants are eliminated, which is crucial for effective lapping.

4. Lapping The actual lapping is performed using a lapping plate and an appropriate abrasive compound. The valve seat (the fixed part of the valve) and the gate (the movable part) are often lapped together to ensure they match perfectly. The operator applies the compound and works the gate against the seat in a circular motion, gradually wearing down any high spots and achieving a smooth, flat surface.

5. Cleaning and Polishing After sufficient lapping, the surfaces are cleaned once again to remove any residual abrasive material. Polishing may also be applied to enhance the finish.

6. Reassembly and Testing Once lapping is complete, the valve is reassembled. It is crucial to perform tests to confirm that the valve seals correctly and operates as expected.

Tools and Materials

The primary tools required for lapping include a lapping plate, lapping compound (often silicon carbide or aluminum oxide), and hand tools for disassembly and reassembly. The lapping plate is typically made of a hard, flat material to provide a stable surface for the lapping process.

Conclusion

Gate valve lapping is a vital maintenance procedure that plays a significant role in ensuring the efficient and reliable operation of valves. By restoring the sealing surfaces, lapping can prevent leaks and prolong the lifespan of gate valves. Regular maintenance, including lapping, helps avoid costly downtime and enhances the overall performance of fluid control systems. Understanding the lapping process and its benefits equips operators and maintenance personnel to keep gate valves in optimal condition, ensuring safety and efficiency in their operations.

-

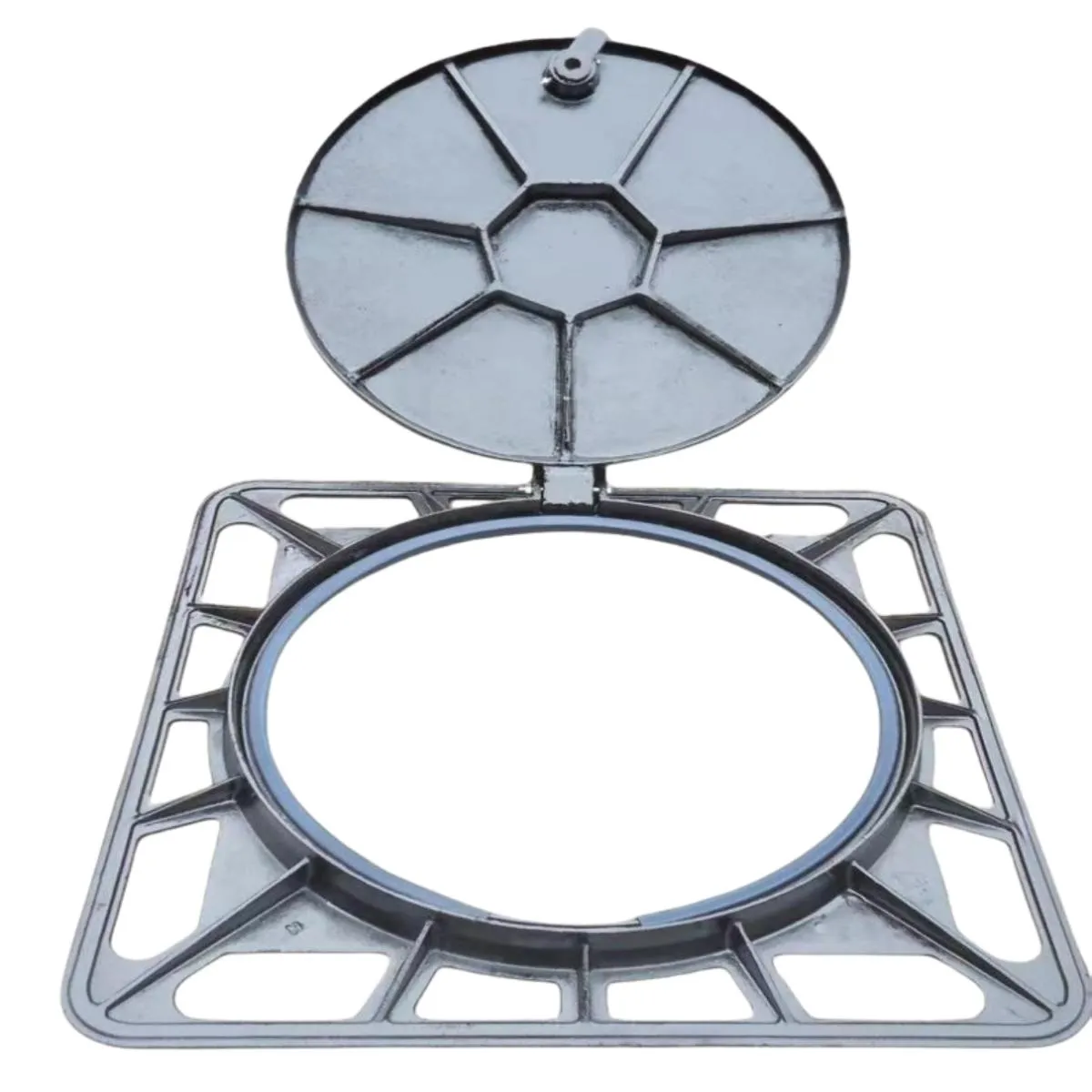

Square Sewer Cover Enhances Urban SafetyNewsAug.01,2025

-

Pipe Fitting Requires Precise AlignmentNewsAug.01,2025

-

Manhole Step Is DurableNewsAug.01,2025

-

Manhole Cover Is Found WorldwideNewsAug.01,2025

-

Hole Cover Frame On RoadsNewsAug.01,2025

-

Gully Grate Improves Road SafetyNewsAug.01,2025

-

Man Hole Cover Round Load CapacityNewsJul.31,2025