dresser 360 repair clamp

The Dresser 360 Repair Clamp A Comprehensive Guide to Its Uses and Benefits

In the world of pipeline repair, the Dresser 360 repair clamp stands out as a formidable solution to a variety of issues that can arise in both water and gas pipelines. This innovative clamp has become a vital tool for utility companies, contractors, and maintenance teams looking to quickly and efficiently address leaks, fractures, or compromises in pipeline integrity. In this article, we will explore the Dresser 360 repair clamp's design, applications, advantages, and some practical tips for using it.

Design Features

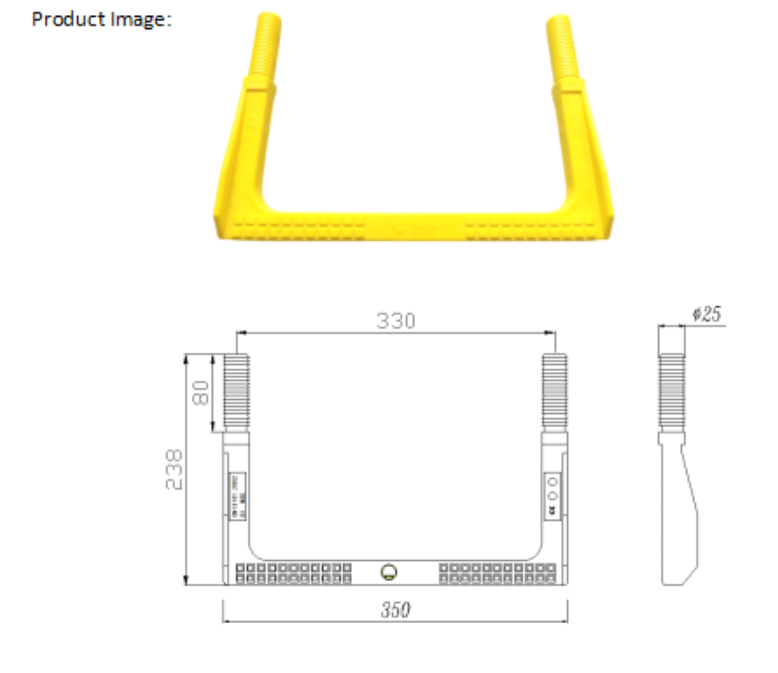

The Dresser 360 repair clamp boasts a robust design that is engineered to provide a reliable and durable solution for pipeline repairs. Typically constructed from high-grade materials such as stainless steel or ductile iron, the clamp is designed to withstand harsh environmental conditions and the stresses associated with high-pressure systems. Its unique 360-degree design allows it to encircle the damaged area completely, providing uniform pressure and a reliable seal along the pipe's circumference.

The clamp features a series of gaskets that conform to the surface of the pipe, filling in gaps and creating a leak-proof barrier. This flexibility in design accommodates a variety of pipe sizes and shapes, making it versatile for different applications. The ease of installation is another significant advantage; many clamps can be installed with minimal tools and equipment, enabling maintenance teams to execute repairs swiftly without extensive downtime.

Applications

One of the primary applications of the Dresser 360 repair clamp is in water distribution systems, where leaks can lead to significant water loss and costly repairs. These clamps can be used effectively on various materials, including cast iron, PVC, and steel, making them ideal for retrofitting existing infrastructure.

In addition to water systems, the Dresser 360 repair clamp is vital in the gas industry, where maintaining the integrity of pipelines is critical for safety and operational efficiency. Any gas leak can pose severe risks, and the timely use of these clamps can prevent catastrophic failures and ensure compliance with regulatory standards.

Furthermore, the versatility of the Dresser 360 allows it to be used in industrial applications, such as cooling and heating systems, where leaks need to be addressed promptly to prevent costly shutdowns. Its capacity to provide a quick fix means that operations can resume with minimal delay.

Advantages

The Dresser 360 repair clamp comes with numerous benefits that make it an invaluable asset for anyone involved in pipeline maintenance. First and foremost, its reliable design provides an immediate way to seal leaks and prevent further damage to the pipeline infrastructure.

dresser 360 repair clamp

Moreover, the clamp's installation process is generally straightforward, allowing personnel to perform repairs quickly. This speed minimizes disruption to services, reduces labor costs, and decreases the potential for lost revenue due to downtime.

Another significant advantage is the durability of the Dresser 360. Unlike temporary patches that may fail under pressure, the repair clamp is built to last, providing a long-term solution that reduces the need for frequent repairs and maintenance.

Installation Tips

When working with the Dresser 360 repair clamp, it is essential to follow proper installation practices to ensure maximum effectiveness. Here are some tips

1. Assessment Before installation, thoroughly assess the damage to determine the appropriate size and type of clamp needed.

2. Surface Preparation Clean the area around the leak to ensure the clamps can make proper contact with the pipe. Any corrosion or debris can compromise the clamp's sealing capability.

3. Alignment Position the clamp so that it fully encircles the damaged area, ensuring that the gaskets are aligned correctly to provide an even seal.

4. Torque Settings Use a torque wrench to tighten the bolts as specified by the manufacturer. Over-tightening can damage the pipe or clamp, while under-tightening may lead to leaks.

5. Inspection After installation, inspect the clamp to confirm that it is securely in place and that no further leaks are present.

Conclusion

The Dresser 360 repair clamp is an essential tool for maintaining the safety and integrity of pipelines in various industries. Its robust design, versatility, and ease of use make it an ideal solution for addressing leaks and damage promptly and efficiently. By following proper installation techniques, utility companies and contractors can ensure that they leverage the full benefits of this innovative repair solution, safeguarding their infrastructure for years to come.

-

The Essential Component for Safe Urban InfrastructureNewsMay.14,2025

-

The Backbone of Urban InfrastructureNewsMay.14,2025

-

Practical and Stylish Solutions for Your Drainage NeedsNewsMay.14,2025

-

Lamphole Frame and Cover: Essential for Urban InfrastructureNewsMay.14,2025

-

A Seamless and Aesthetic SolutionNewsMay.14,2025

-

A Must-Have for Safety and DurabilityNewsMay.14,2025

-

Pipe Repair Clamps: Your Ultimate Solution for Efficient RepairsNewsMay.09,2025