48 inch butterfly valve specifications and applications for industrial use

Understanding the 48-Inch Butterfly Valve Key Features and Applications

Butterfly valves are a widely used type of flow control device, particularly in large-scale industrial applications. Among their various sizes, the 48-inch butterfly valve stands out due to its capacity to manage significant volumes of fluid with efficiency and reliability. This article explores the key features, advantages, and applications of the 48-inch butterfly valve.

Key Features

1. Design and Structure The primary characteristic of a butterfly valve is its simple yet effective design. A 48-inch butterfly valve consists of a disc positioned in the center of the valve body. This disc rotates 90 degrees to either fully open or close the flow of fluid, making it one of the quickest and most efficient valve types available. The 48-inch size allows for increased flow rates, catering to industries such as water treatment, oil and gas, and chemical processing.

2. Material Selection These valves are available in various materials, including cast iron, stainless steel, and PVC. The choice of material depends on the specific application and the type of fluid being transported. For instance, stainless steel is often preferred for corrosive environments, whereas cast iron may suffice for less aggressive applications.

3. Sealing Mechanism Butterfly valves can feature different sealing types, including soft-seated and metal-seated designs, each suited for different pressure and temperature ranges. The sealing integrity is crucial for preventing leaks and ensuring optimal operation, especially in high-pressure systems.

4. Actuation Options Depending on the operational demands, the 48-inch butterfly valve can be operated manually or automatically. Manual operations typically involve a handwheel or lever, while automatic actuation may utilize electric, pneumatic, or hydraulic actuators. This flexibility allows for seamless integration into automated systems, enhancing operational efficiency.

Advantages

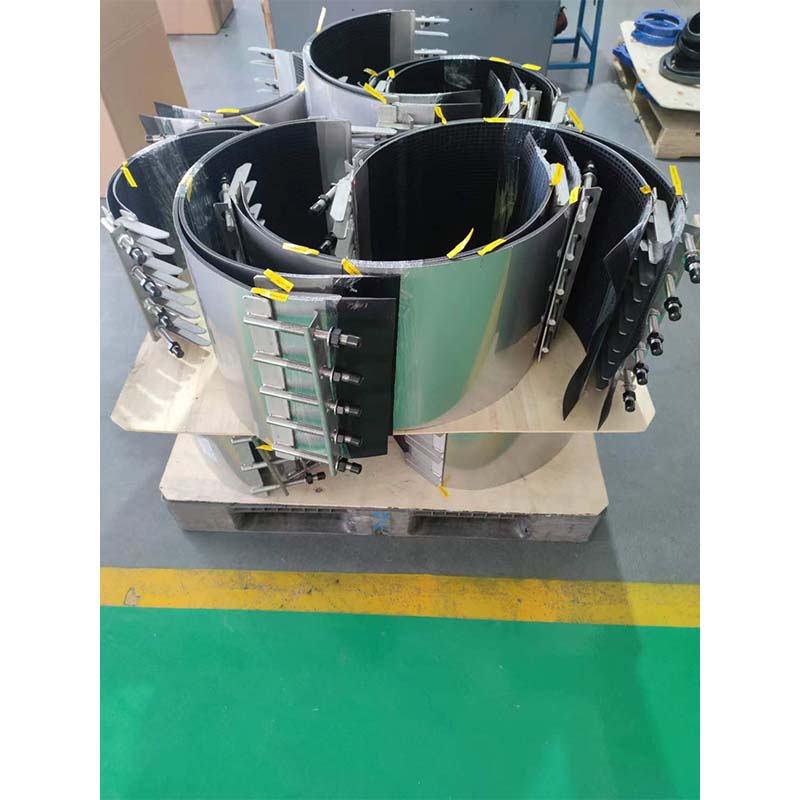

48 inch butterfly valve

1. Space Efficiency Due to their compact design, butterfly valves require less space compared to other valve types like gate valves or ball valves. This makes them ideal for installations where space is limited.

2. Low Torque Requirements The disk design results in lower torque requirements to operate the valve, making it easier to manage even in larger sizes. As a result, the actuators used with these valves can be smaller and less expensive.

3. Cost-Effectiveness The manufacturing process for butterfly valves is generally less complex than for other valve types, contributing to their cost-effectiveness. For large diameter options like the 48-inch model, this translates into savings in both material costs and installation.

4. Versatile Applications Butterfly valves are suitable for various media, including water, sewage, oil, and gases, making them versatile tools in different sectors.

Applications

The 48-inch butterfly valve is particularly beneficial in industries that require high flow rates and effective control. They are commonly used in

- Water Treatment Facilities To regulate the flow of water in various stages of treatment and distribution. - Chemical Processing Plants For managing corrosive fluids and ensuring safety in chemical transport. - Power Plants To control water and steam flow within cooling systems and boiler applications. - Oil and Gas Industries For regulating the flow of crude oil and natural gas.

In conclusion, the 48-inch butterfly valve is a vital component in many industrial processes due to its efficient design, versatility, and cost-effectiveness. Its ability to handle substantial flow while maintaining reliability makes it an essential choice for engineers and operators across various sectors. By understanding its features and applications, industries can optimize their systems and ensure safe and efficient operations.

-

The Essential Component for Safe Urban InfrastructureNewsMay.14,2025

-

The Backbone of Urban InfrastructureNewsMay.14,2025

-

Practical and Stylish Solutions for Your Drainage NeedsNewsMay.14,2025

-

Lamphole Frame and Cover: Essential for Urban InfrastructureNewsMay.14,2025

-

A Seamless and Aesthetic SolutionNewsMay.14,2025

-

A Must-Have for Safety and DurabilityNewsMay.14,2025

-

Pipe Repair Clamps: Your Ultimate Solution for Efficient RepairsNewsMay.09,2025