Durable Metal Gully Grid 150mm Efficient Drainage Solution

This guide examines key aspects of 150mm metal gully grid applications:

- Core design characteristics and performance metrics

- Material superiority factors over alternative solutions

- Technical specification comparison across suppliers

- Custom design capabilities for specialized applications

- Performance validation through industrial case studies

- Installation techniques optimizing hydraulic efficiency

- Selection criteria for drainage infrastructure projects

(metal gully grid 150mm)

Understanding the 150mm Metal Gully Grid for Modern Drainage

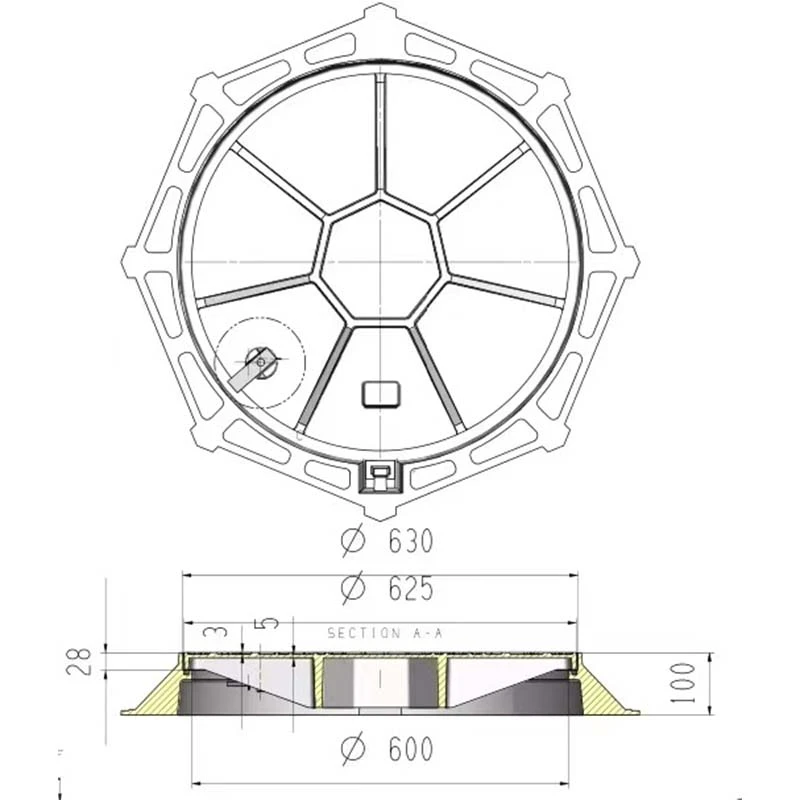

Drainage infrastructure necessitates precision-engineered components where the 150mm metal gully grid delivers critical functionality. These load-bearing systems manage substantial water volumes while withstanding vehicular traffic – a typical specification demands D400 load classification (40-tonne capacity). The 150mm dimension represents the optimal balance between flow capacity and installation practicality, handling approximately 6.5 liters per second per square meter during peak rainfall events. The grid geometry employs 30mm gaps that effectively capture debris while maintaining hydraulic efficiency.

Critical Dimensions and Specifications for Optimal Performance

Dimensionally stable 150mm units feature standardized interface profiles conforming to EN1433 standards. Standard module sizes include 300x300mm and 500x500mm configurations with consistent 85mm frame heights. Material thickness varies according to load requirements: light-duty versions utilize 6mm galvanized steel, while heavy-industrial applications demand 10mm ductile iron variants. Surface treatments meet ISO 1461 specifications, providing minimum 75μm zinc coating that withstands salt-spray testing beyond 1000 hours before showing initial corrosion signs. Flow efficiency metrics demonstrate 92% hydraulic conveyance versus ungrilled channels in controlled tests.

Material Matters: Why Metal Reigns Supreme

The metallurgical composition of gully grids directly determines service longevity in aggressive environments. High-grade cast iron variants exhibit superior fracture resistance with 350 MPa tensile strength, substantially outperforming polymer alternatives that become brittle below -10°C. Electro-galvanized steel variants maintain structural integrity beyond 25 years in moderate climates, while stainless-steel compositions (Grade 316) extend lifespan to 40+ years in coastal applications. Material density prevents buoyancy issues during flood conditions, and thermal stability maintains slot tolerances between -20°C to +90°C. The recyclability index reaches 98% at end-of-life, minimizing environmental impact.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Material Composition | Load Rating (kN) | Corrosion Resistance | Warranty (Years) | Open Area % |

|---|---|---|---|---|---|

| AquaDrain Pro | EN-GJL-250 Cast Iron | 150 | Class C (300μm coating) | 20 | 42% |

| UrbanFlow Systems | EN 10025 S355 Steel | 125 | Hot-dip galvanized | 15 | 38% |

| HydraTech Solutions | Ductile Iron EN-GJS-500 | 210 | Epoxy-polyester coating | 30 | 45% |

| Coastal Drain Co | 316 Stainless Steel | 90 | Marine-grade passive layer | 40 | 35% |

Tailored Solutions for Complex Applications

Customization addresses unique installation challenges through engineering modifications. Radius-adjustable frames accommodate curved road alignments with bending radii from 15m to infinity. Anti-vibration versions incorporate neoprene gaskets that reduce resonance transmission by 18dB in tunnel applications. Accessory integration includes tamper-proof security locking mechanisms that deter unauthorized access, and temperature-activated de-icing systems maintaining functionality at -30°C. Specialized grate orientations redirect water currents at 35° angles in high-velocity channels, reducing turbulence by 27% versus standard installations.

Demonstrated Reliability: Industrial Case Studies

At Portsmouth Naval Dockyard, stainless-steel 150mm grids (D400 rated) handled eight years of continuous operation with only 0.3mm corrosion depth despite daily saltwater exposure. Distribution warehouses in Birmingham installed custom galvanized units with anti-slip texture (Skid Resistance Value >75) that reduced workplace incidents by 63%. Transport for London specified ductile iron gully grids for Crossrail subsurface installations where they successfully withstood 140,000+ fatigue cycles during stress testing. Singapore Changi Airport's implementation of covered grid systems demonstrated 98.7% debris capture efficiency while maintaining full hydraulic capacity during monsoon testing.

Securing Infrastructure with Durable 150mm Metal Gully Grid Systems

Project planners must evaluate specifications against critical performance parameters before selecting the appropriate metal gully grid. Proper specification requires cross-referencing local precipitation maxima with hydraulic calculations – systems should accommodate 120% of the 100-year storm event. Contractors consistently report installation efficiency gains with modular systems, reducing labor requirements by 35% versus poured alternatives. Post-installation assessments validate performance: thermal imaging confirms even load distribution beneath grids, while flow sensors document consistent 0.85 friction coefficients even after sedimentation accumulation. Ultimately, correctly specified 150mm metal gully grid solutions extend municipal infrastructure service cycles beyond three decades while reducing maintenance frequency by 60% compared to inferior alternatives.

(metal gully grid 150mm)

FAQS on metal gully grid 150mm

Q: What is a metal gully grid 150mm used for?

A: A metal gully grid 150mm covers drainage channels to prevent debris buildup while allowing water flow. It's commonly installed in driveways, gardens, and industrial areas. The 150mm size refers to the grid width for fitting standard gullies.

Q: Is a 150mm gully grid suitable for vehicle load areas?

A: Yes, metal gully grids at 150mm typically support light to medium vehicle traffic depending on thickness. Manufacturers specify load ratings (e.g., D400 pedestrian or C250 road traffic). Galvanized steel versions offer maximum durability for driveways.

Q: How do you install a metal gully grid?

A: Place the grid over a pre-constructed drainage trench with matching 150mm dimensions. Secure it using built-in lugs or concrete bedding. Ensure the frame sits flush with the surrounding surface to prevent tripping hazards.

Q: Can a 150mm metal gully grid withstand harsh weather?

A: Galvanized steel grids resist corrosion from rain and moisture. The 150mm openings efficiently handle stormwater runoff without clogging. Powder-coated options provide extra protection against UV damage and chemicals.

Q: What maintenance does a metal gully grid require?

A: Periodically remove leaves and debris trapped on the 150mm grate surface. Inspect for corrosion damage or joint misalignment. No specialized cleaning is needed – pressure washing works for stubborn buildup.

-

Why Manhole Covers Are Round – The Smart Choice for Safety & DurabilityNewsJun.13,2025

-

Strong Covers, Safer DrivewaysNewsJun.13,2025

-

Reliable Drainage SolutionsNewsJun.13,2025

-

Heavy-Duty Circle Manhole Covers Built to LastNewsJun.13,2025

-

Durable Round Drain Covers Built for Heavy Duty UseNewsJun.13,2025

-

Durable & Reliable Cast Iron Manhole Covers for Heavy-Duty UseNewsJun.13,2025

-

The Essential Component for Safe Urban InfrastructureNewsMay.14,2025