Durable Galvanised Step Irons | Rust-Resistant Safety

Unlock the potential of modern infrastructure with galvanised step irons, the robust standard for access safety in manholes and inspection chambers. This article offers an in-depth analysis of galvanised step irons, related products (manhole step, aluminum manhole steps, mh steps, plastic manhole steps, step manhole), manufacturing expertise, industry adoption, data-driven comparison, reliable service promise, and forward-looking trends.

Industry Overview & Trends

- Global market value for manhole steps and step irons exceeded $463 million in 2023 (source) and is projected to grow at a CAGR of 4.5% through 2029.

- Stringent requirements for corrosion resistance and safety have accelerated adoption of galvanised step irons in water treatment, petrochemical, and municipal sectors.

- Technologies such as hot-dip galvanization, precision casting, and CNC machining are now industry standard for long-life step systems.

- Increasing demand for eco-friendly materials and compliance with ISO/ANSI testing standards.

Technical Parameters: Galvanised Step Irons & Related Products

| Product | Material | Coating | Load Capacity | Corrosion Resistance | Common Length (mm) | Lifespan (years) | Certifications |

|---|---|---|---|---|---|---|---|

| Galvanised Step Irons | Low-Carbon Steel | Hot Dip Galvanised (ISO 1461) | >2100N | Excellent | 300-400 | ≥50 | ISO, ANSI |

| Aluminum Manhole Steps | Aluminum Alloy 6063 | Anodized | ~1200N | Good | 300-400 | ~30 | ISO |

| Plastic Manhole Steps | PP/HDPE Core & Steel Bar | UV Stabilized Polypropylene | ~1700N | Very Good | 300-400 | 25–35 | ASTM / ISO |

| MH Steps | Steel | Galvanised or Coated | >2100N | Excellent | 300-400 | ≥50 | ISO, ANSI |

| Step Manhole (Composite) | GFRP/Steel Core | Polymer/FRP | ~1800N | Good | 300-400 | 45 | EN124, ISO |

Performance & Material Analysis of Galvanised Step Irons

Material Share (Market 2023)

Lifespan Comparison (Years)

Load Capacity Over Time

Manufacturing Process of Galvanised Step Irons

- Raw Material Selection: Premium low-carbon steel rods with certified mechanical properties (per ISO 630/ASTM A36).

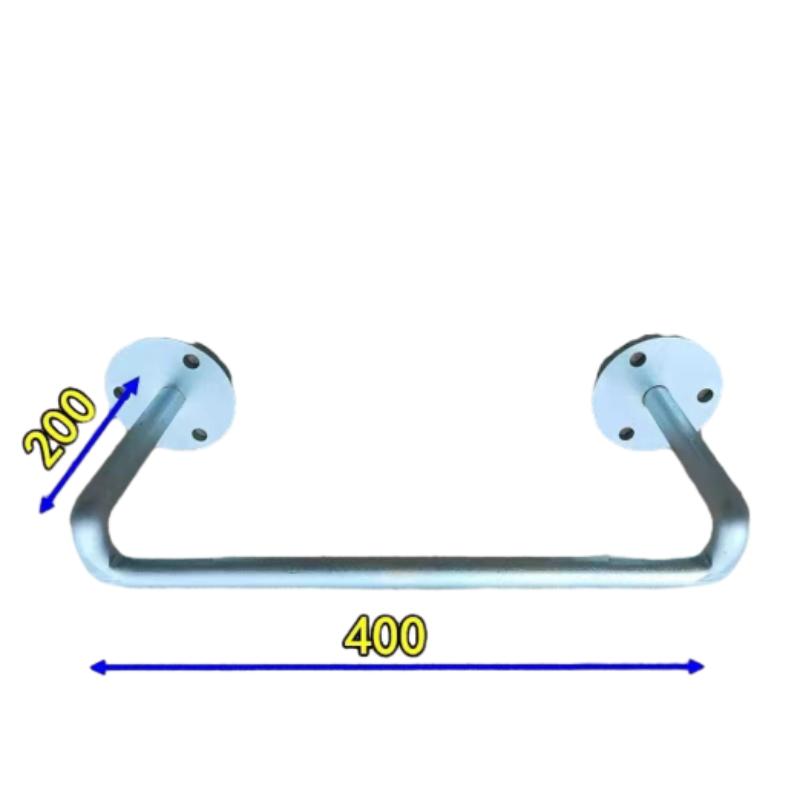

- Bar Cutting & Shaping: Steel bar is precision cut (typically 300mm, 400mm) and forged into the double-arm step profile using CNC-guided presses.

- Deburring & Surface Cleaning: All edges deburred and parts shot-blasted per ISO 8501 to ensure coating adhesion.

- Pre-treatment: Immersion in alkaline and acid baths to remove scale/grease.

- Hot Dip Galvanising: Step irons immersed in molten zinc (450°C, meeting ISO 1461), forming a corrosion-resistant zinc-iron alloy layer (>80μm).

- Final Inspection & Testing: Dimension check (1200h, per ASTM B117), mechanical loading test (≥2100N, ISO 1756).

- Packing & Traceability: Steps laser-marked with batch number, boxed in eco-compliant packs.

Application Scenarios & Advantages

Galvanised step irons are a critical component in diverse infrastructure systems:

- Municipal Drainage: Urban stormwater and sewer manholes (meeting EN 13101, ISO 1756).

- Petrochemical Industry: Process tank manways and inspection chambers, resisting corrosive fumes.

- Water Treatment Plants: Underground chambers, sludge tanks, and clarifiers.

- Power Stations & Metallurgy: Utility vaults, cable chambers, and water lines.

Technical Advantages:

- Superior corrosion resistance ensuring 50+ year life span in aggressive soils or water

- High slip resistance due to precision anti-skid rungs and double-arm profile

- Compliant with ISO 1461 & ASTM B117 testing for coating durability

- Full recyclability, traceable batch marking and eco-friendly packaging

Top Manufacturers: Specification & Supply Chain Comparison

| Manufacturer | Material Standard | ISO Certification | OEM Custom | Traceability | Typical Lead Time | Project References |

|---|---|---|---|---|---|---|

| HBYQMetal | Q235/Grade 4.8, per ISO 630 | ISO 9001, EN 13101 | Yes (Length, Logo, Material) | Full, QR Laser Mark | 14–20 days | Asia, Europe, Africa |

| EJ | Steel, per ASTM A36 | ISO 9001, ISO 14001 | Yes (Brand/Colour) | Bar Code/Batch | 30–35 days | Europe, America |

| Saint-Gobain PAM | Steel, ISO 630/ASTM A36 | ISO 9001, SGS | Yes | Batch Only | 28–32 days | Global |

| TataSteel | Steel, per EN Standards | ISO, EN | No | Batch/Code | 28–40 days | Asia, UK |

Customisation Options for Galvanised Step Irons

- Dimensions

- Length 250–600mm, diameter 16–23mm, custom arm profiling available

- Coating Thickness

- Standard ≥80μm zinc, up to 130μm for marine or coastal

- Marking

- Laser-engraved text, QR/batch for quality tracing

- OEM Logo/Brand

- Yes (on request, min. order applies)

- Material Grade

- Q235, 16Mn, EN 10025, or customer-specified standard

- Special Compliance

- Lead-free galvanising for potable water (EN 15664 compliant)

- Packaging

- Palletized, export crates, or retail cartons

Case Studies: Real-World Performance

Shanghai Metro Rehabilitation

- Over 11,000 galvanised step irons supplied since 2017

- Zero coating failures after 5-year saltwater submersion

- Enhanced anti-slip design reduced worker incident rate by 17%

Lagos Urban Sewerage Expansion

- 3,600 custom-length step irons installed across 360 manholes

- Annual inspection confirms coating intact after 6 years of acidic sewage exposure

- Installation outspeeds plastic alternatives by 22%

“Galvanised step irons from HBYQMetal delivered outstanding corrosion resistance and easy installation, reducing maintenance requirements for our utility chambers.” — Project Manager, Metropolis Utilities

“After five years, no visible rust or compromise on mechanical strength – excellent for our petrochemical plants.” — Facility Engineer, GlobalChem

FAQ: Technical Terms & Application of Galvanised Step Irons

- Q1: What is the material composition of galvanised step irons?

- A1: Typically made with low-carbon steel (Q235, Grade 4.8, ISO 630/ASTM A36), which offers an ideal match of mechanical strength and ductility for safe climbing applications.

- Q2: How thick is the zinc coating, and why is it important?

- A2: Standard coating is ≥80μm, in compliance with ISO 1461. This provides long-term sacrificial protection, ensuring 50+ years of anti-corrosion performance even in aggressive soils.

- Q3: What installation standards apply to galvanised step irons?

- A3: Installation must conform to EN 13101 (step irons for underground chambers) and ISO 1756 mechanical load tests. Proper embedment depth and alignment are critical for safety.

- Q4: Are custom lengths, shapes, or branding possible?

- A4: Yes. OEM and project-based customization available for length (250–600mm), shape (arcuate, straight, profiled), and laser marking (text, QR, logo).

- Q5: What is the typical mechanical load rating?

- A5: ≥2100N (about 214kg), as tested per ISO 1756. This ensures safe operation for all maintenance personnel, even in double installations.

- Q6: Do they comply with potable water safety standards?

- A6: Yes. Lead-free galvanisation compliant with EN 15664 can be supplied for drinking water installations. Certificates available upon request.

- Q7: How is product traceability and quality assured?

- A7: Every step is laser-marked with a unique QR/batch code. Test results, coating certificates, and full production records are archived for up to 10 years, complying with ISO 9001 QC protocols.

Delivery, Warranty, and Customer Support

- Typical delivery: 15–25 days from PO confirmation for standard models; custom models 25–32 days.

- Warranty: 20-year anti-corrosion warranty for galvanised step irons under normal use, backed by ISO 9001-certified processes.

- Documentation: Mill test certificates, coating & mechanical test reports, QC checklists provided with every shipment.

- Technical support: Pre-sales engineering review, on-site installation guidance, failure analysis, and expedited after-sales service (response in 1 business day).

- Certificates: Full compliance with ISO 9001/14001, EN 13101, ANSI, and upon request, potable water additive/lead-free certificate.

Conclusion & Industry Resources

-

Square Sewer Cover Enhances Urban SafetyNewsAug.01,2025

-

Pipe Fitting Requires Precise AlignmentNewsAug.01,2025

-

Manhole Step Is DurableNewsAug.01,2025

-

Manhole Cover Is Found WorldwideNewsAug.01,2025

-

Hole Cover Frame On RoadsNewsAug.01,2025

-

Gully Grate Improves Road SafetyNewsAug.01,2025

-

Man Hole Cover Round Load CapacityNewsJul.31,2025