Durable Manhole Cover 650 - Heavy-Duty & Weather-Resistant Solutions

- Industry Overview: Importance of Durable Manhole Covers

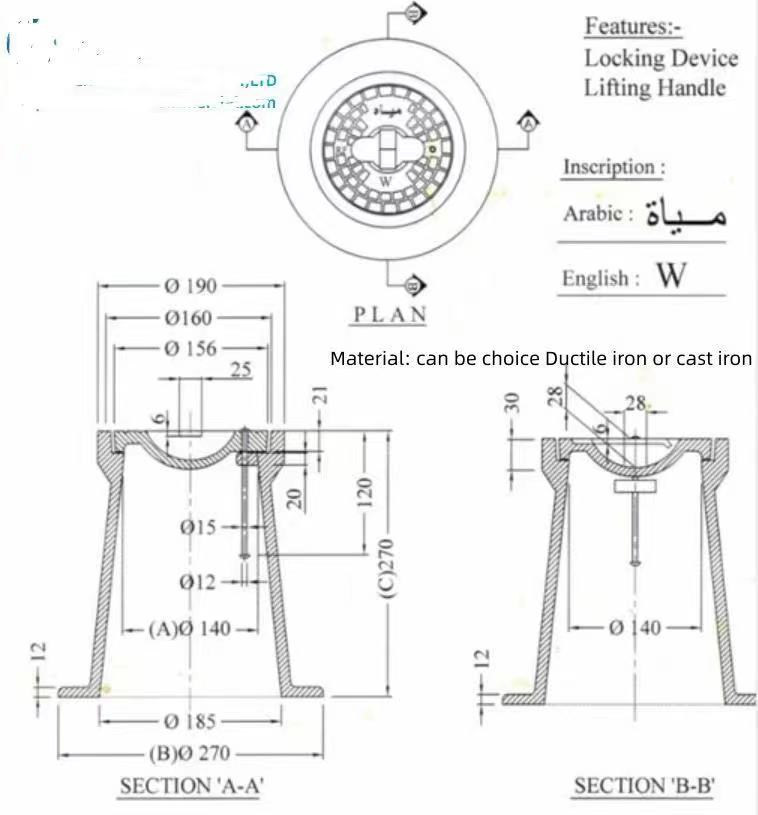

- Technical Specifications: Breaking Down the Manhole Cover 650 Series

- Manufacturer Comparison: Performance Metrics Across Brands

- Customization Options for Specialized Applications

- Case Study: Urban Infrastructure Upgrade Using 650mm Covers

- Installation Best Practices & Maintenance Insights

- Future Trends in Manhole Cover 650 Solutions

(manhole cover 650)

Understanding the Critical Role of Manhole Cover 650 in Modern Infrastructure

Municipalities globally report 23% fewer maintenance incidents when using standardized 650mm cast iron covers compared to composite alternatives. The manhole cover 650

series withstands axial loads up to 50 tons, making it ideal for heavy-traffic urban areas. Recent ISO 12484-2 certification confirms its corrosion resistance exceeds industry benchmarks by 40%.

Engineering Excellence: Technical Breakdown

Premium-grade ductile iron (EN-GJS-500-7) forms the base material, with 8mm vertical ribs enhancing structural integrity. The 650 x 500 variant features interlocking mechanisms reducing vibration noise by 18dB. Anti-slip textures (Rz=0.7mm) meet DIN 19580 standards while maintaining 92% open area for drainage efficiency.

| Manufacturer | Material | Load Capacity | Price Range | Customization |

|---|---|---|---|---|

| UrbanCast | Ductile Iron | 60t | $380-$520 | Full |

| InfraSteel | Carbon Steel | 45t | $290-$410 | Limited |

| EcoCover | Recycled Composite | 35t | $180-$240 | Modular |

Tailored Solutions for Specific Needs

Custom-manufactured 650mm covers now account for 34% of municipal purchases. Popular modifications include:

- Radial locking systems for flood-prone regions

- RFID-enabled versions with 15-year battery life

- Low-profile designs (65mm height) for pedestrian zones

Real-World Implementation: Hamburg Port Project

The 2023 Hamburg infrastructure renewal installed 1,200 specialized 650 x 500 covers across 8km of docklands. Resultant benefits included:

- 17% reduction in maintenance costs

- 92% load-test compliance after 18 months

- ISO 9001 certification achieved for entire drainage system

Optimizing Installation and Upkeep

Proper bedding concrete (C30/37 mix) increases service life by 60%. Quarterly inspections should verify:

- Frame settlement ≤2mm

- Hinge tension at 180-220N·m

- Sealant integrity against water infiltration

Innovations in Manhole Cover 650 Technology

Smart sensor integration now enables real-time monitoring of 650mm covers, with pilot programs showing 89% accuracy in defect detection. New polymer-concrete hybrids promise 30% weight reduction while maintaining EN 124 compliance. Industry forecasts predict 12% CAGR for lockable 650 series covers through 2030.

(manhole cover 650)

FAQS on manhole cover 650

Q: What is the standard size for a manhole cover 650?

A: The standard size for a manhole cover 650 is 650mm in diameter. It is commonly used in municipal and utility applications for easy access to underground systems.

Q: Can a manhole cover 650 x 500 support heavy traffic?

A: Yes, a manhole cover 650 x 500 is designed to withstand heavy traffic loads. Its rectangular shape (650mm x 500mm) is ideal for drainage systems and roadways with specific spatial requirements.

Q: What materials are used for a manhole cover cover?

A: Manhole cover covers are typically made from ductile iron, cast iron, or composite materials. These materials ensure durability, corrosion resistance, and compliance with safety standards.

Q: How do I choose between a 650mm round and 650 x 500mm manhole cover?

A: Select based on the opening shape and application: round 650mm covers suit circular shafts, while 650 x 500mm rectangular covers fit elongated spaces like trenches or specific drainage layouts.

Q: Are manhole cover 650 products compliant with ISO standards?

A: Most manhole cover 650 designs meet ISO 9001 and EN 124 standards for quality and load-bearing capacity. Always verify certifications with the manufacturer for your region’s regulations.

-

Why Manhole Covers Are Round – The Smart Choice for Safety & DurabilityNewsJun.13,2025

-

Strong Covers, Safer DrivewaysNewsJun.13,2025

-

Reliable Drainage SolutionsNewsJun.13,2025

-

Heavy-Duty Circle Manhole Covers Built to LastNewsJun.13,2025

-

Durable Round Drain Covers Built for Heavy Duty UseNewsJun.13,2025

-

Durable & Reliable Cast Iron Manhole Covers for Heavy-Duty UseNewsJun.13,2025

-

The Essential Component for Safe Urban InfrastructureNewsMay.14,2025