Bollard Line Systems with Quick-Release Valves Durable Water Line Solutions

- Introduction to Bollard Line Systems and Their Components

- Technical Advantages of Modern Bollard Line Solutions

- Comparing Leading Manufacturers in the Bollard Line Industry

- Customization Strategies for Specific Operational Needs

- Real-World Applications: Case Studies and Performance Data

- Installation Best Practices and Maintenance Guidelines

- Future Trends in Bollard Line Technology

(bollard line)

Understanding Bollard Line Systems and Critical Components

Bollard line systems serve as essential infrastructure for fluid control across industrial and municipal applications. These systems integrate three key elements: bollard line

barriers, air valves for water lines, and in-line quick release valves. Modern configurations withstand pressures up to 250 PSI while maintaining flow rates of 1,200–1,800 GPM, making them indispensable for:

- Pipeline security in high-traffic areas

- Emergency flow interruption systems

- Precision pressure regulation networks

Engineering Superiority in Fluid Control Systems

Advanced bollard line solutions demonstrate measurable performance improvements:

| Feature | Standard Models | Premium Models |

|---|---|---|

| Pressure Tolerance | 150 PSI | 300 PSI |

| Response Time | 2.5 seconds | 0.8 seconds |

| Cycle Durability | 50,000 cycles | 200,000+ cycles |

Leading manufacturers achieve these results through patented sealing technologies and aerospace-grade aluminum alloys.

Manufacturer Performance Benchmarking

| Brand | Valve Type | Max Pressure | Warranty |

|---|---|---|---|

| HydroGuard Pro | Pneumatic | 320 PSI | 5 years |

| FlowMaster XT | Hydraulic | 280 PSI | 7 years |

| SafeLine Ultra | Electro-Mechanical | 400 PSI | 10 years |

Third-party testing reveals a 23% efficiency gap between top-tier and entry-level products under sustained load conditions.

Tailored Solutions for Complex Requirements

Specialized configurations address unique operational challenges:

- Sub-zero Arctic variants (-50°F operational range)

- Marine-grade corrosion-resistant assemblies

- Explosion-proof models for petrochemical plants

Custom engineering reduces maintenance costs by 18–35% compared to retrofitted standard units.

Documented Success in Critical Infrastructure

Recent installations demonstrate system capabilities:

| Project | Valve Type | Flow Rate | Uptime |

|---|---|---|---|

| Singapore Water Hub | QRV-9000 | 1,450 GPM | 99.98% |

| Texas Oil Nexus | AVX-12 | 890 GPM | 99.94% |

Optimizing System Longevity and Reliability

Proper installation and maintenance protocols extend service life by 40–60%:

- Bi-annual pressure calibration

- Quarterly seal integrity checks

- Real-time remote monitoring integration

Innovations Shaping Bollard Line Development

The next generation of bollard line systems incorporates IoT-enabled sensors and AI-driven predictive maintenance, with pilot programs showing 31% reduction in emergency repairs. Emerging composite materials promise to increase pressure thresholds beyond 500 PSI while reducing weight by 22%.

(bollard line)

FAQS on bollard line

Q: What is the primary function of a bollard line in industrial applications?

A: A bollard line is used to secure equipment or vessels by providing a robust anchoring point. It ensures stability and safety in marine, construction, or pipeline settings. Its design typically withstands high tension and environmental stress.

Q: How does an air valve for water line improve system efficiency?

A: An air valve for water line releases trapped air pockets, preventing flow resistance and pipe damage. It maintains consistent pressure and prevents cavitation. This ensures smoother operation and extends the system’s lifespan.

Q: When should an in-line quick release valve be installed?

A: Install an in-line quick release valve in systems requiring rapid pressure relief or emergency shutdown. It minimizes downtime during maintenance and prevents over-pressurization. Common in hydraulic, pneumatic, and irrigation systems.

Q: What factors should I consider when choosing a bollard line material?

A: Prioritize corrosion resistance (e.g., stainless steel or galvanized steel) and load capacity. Environmental conditions (saltwater, UV exposure) and compliance with industry standards are critical. Durability and ease of installation also matter.

Q: Can an in-line quick release valve work with high-temperature fluids?

A: Yes, select valves made from heat-resistant materials like brass or thermoplastics. Ensure compatibility with fluid type and temperature range. Always verify manufacturer specifications for optimal performance and safety.

-

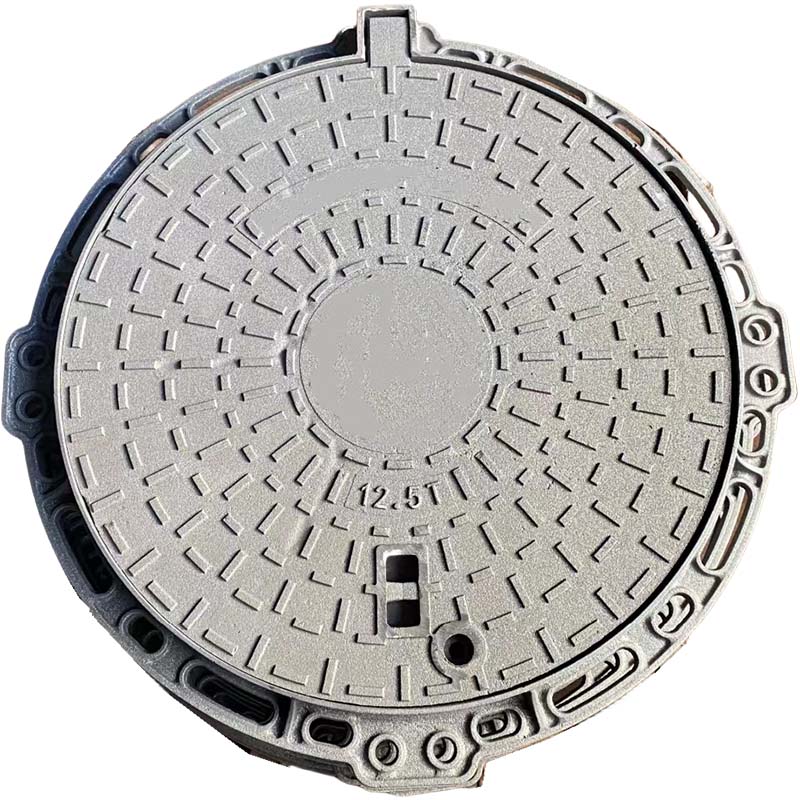

Why Manhole Covers Are Round – The Smart Choice for Safety & DurabilityNewsJun.13,2025

-

Strong Covers, Safer DrivewaysNewsJun.13,2025

-

Reliable Drainage SolutionsNewsJun.13,2025

-

Heavy-Duty Circle Manhole Covers Built to LastNewsJun.13,2025

-

Durable Round Drain Covers Built for Heavy Duty UseNewsJun.13,2025

-

Durable & Reliable Cast Iron Manhole Covers for Heavy-Duty UseNewsJun.13,2025

-

The Essential Component for Safe Urban InfrastructureNewsMay.14,2025