Exploring Various Categories of Butterfly Valves and Their Applications in Industry

Different Types of Butterfly Valves

Butterfly valves are a crucial component in various industrial applications, utilized for controlling flow within pipelines. These valves are particularly favored for their simple design, reliable operation, and ease of maintenance. Understanding the different types of butterfly valves can help engineers and operators make informed decisions that enhance efficiency and performance in their systems.

1. Concentric Butterfly Valve

Concentric butterfly valves, also referred to as centerline butterfly valves, are the most common type. Their design features a disc mounted at the center of the pipe. When the valve is closed, the disc fits snugly against a seal in the valve body, providing an effective shut-off. One of the main advantages of concentric valves is their compact design, making them suitable for applications with limited space. They are ideal for applications involving water, oils, and other non-corrosive fluids.

2. Eccentric Butterfly Valve

Eccentric butterfly valves, commonly known as high-performance butterfly valves, have a disc that is offset from the centerline of the pipe. This design allows for a more efficient flow pattern and reduces the wear on the sealing surfaces. Eccentric valves are often used in applications requiring a tight shut-off or handling slurries and other viscous fluids. The movement of the disc also minimizes turbulence, making these valves suitable for high-pressure and high-temperature applications.

3. Double Eccentric Butterfly Valve

The double eccentric butterfly valve takes the eccentric design a step further, featuring two offsets one at the centerline of the disc and another at the valve’s stem. This advanced design minimizes the friction between the disc and the seal, allowing for smoother operation and longer lifespan. Double eccentric valves are well-suited for high-pressure and high-temperature applications, offering superior sealing capabilities and durability. They are commonly used in chemical processing, oil and gas, and water treatment facilities.

different types of butterfly valves

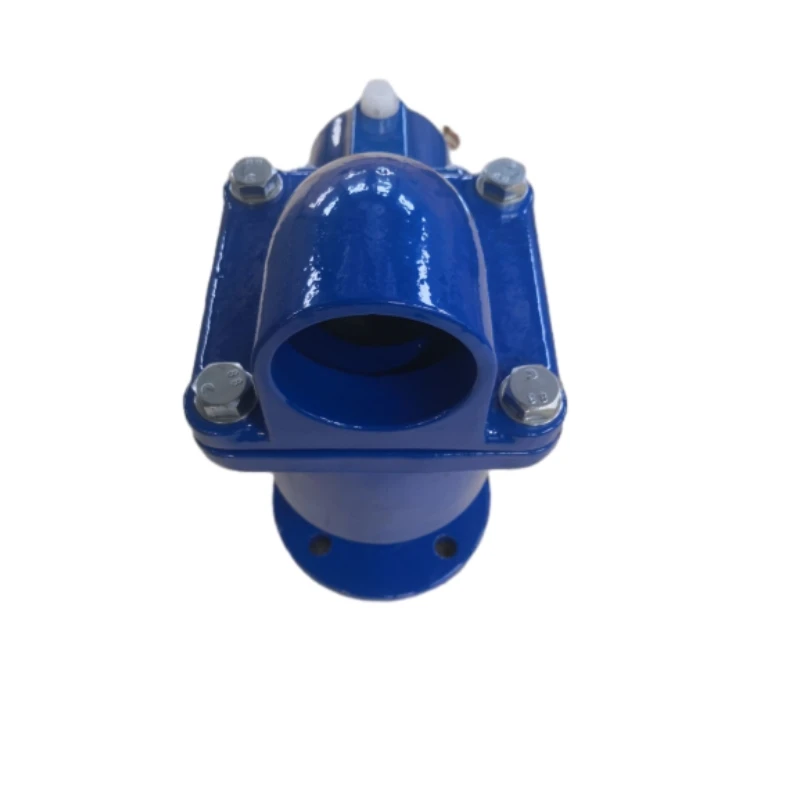

4. Triple Eccentric Butterfly Valve

The triple eccentric butterfly valve, also known as a turbine butterfly valve, has three offsets that optimize the sealing performance and operational efficiency. The first eccentricity is at the disc’s rotation axis, the second at the sealing surface, and the third is related to the valve body. This design completely eliminates contact between the disc and the seat during operation, which significantly reduces wear and prolongs the valve's life. Triple eccentric valves are ideal for demanding applications such as steam, hot water, and corrosive fluids, providing excellent tightness and pressure resistance.

5. Lug Style Butterfly Valve

Lug style butterfly valves differ from traditional butterfly valves in that they are equipped with threaded lugs on the valve body, allowing for easy installation and disassembly. These valves are often utilized in dead-end service applications where the valve needs to be removed without disrupting the pipeline. The lug design also provides enhanced adaptability, fitting seamlessly into various piping systems. They are commonly used in water distribution and HVAC systems.

6. Wafer Style Butterfly Valve

Wafer style butterfly valves are designed to be sandwiched between two flanges of a pipeline. This compact design provides an effective sealing solution with a lower profile, making them suitable for applications where space is limited. They offer a significant advantage in terms of installation flexibility and are often used in systems that experience varying pressure conditions.

Conclusion

Butterfly valves are a versatile choice for controlling flow in various industrial applications, with each type offering unique benefits tailored to specific needs. The selection of the appropriate butterfly valve—whether it be concentric, eccentric, double eccentric, triple eccentric, lug style, or wafer style—depends on factors such as pressure, temperature, and the nature of the fluid being handled. By understanding the different types of butterfly valves, engineers can optimize their systems for improved efficiency and reliability. Properly chosen and maintained butterfly valves can contribute significantly to the performance and longevity of fluid control systems in diverse industries.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025