Durable Ductile Iron Grating for Enhanced Strength and Safety in Construction Applications

Ductile Iron Grating An Essential Element in Modern Infrastructure

Ductile iron grating has emerged as a crucial element in modern infrastructure due to its unique combination of strength, durability, and versatility. Unlike traditional materials, ductile iron offers enhanced mechanical properties, making it a preferred choice in various applications, from industrial facilities to urban environments.

To understand the significance of ductile iron grating, it is essential first to grasp the properties of ductile iron itself. Developed in the 1940s, ductile iron, also known as nodular cast iron, is characterized by its spheroidal graphite structure. This microstructure grants ductile iron its remarkable tensile strength and impact resistance. Compared to grey cast iron, which can be brittle and prone to cracking under stress, ductile iron effectively combines the benefits of both strength and flexibility. As a result, it can withstand heavy loads, making it ideal for grating applications where strength is critical.

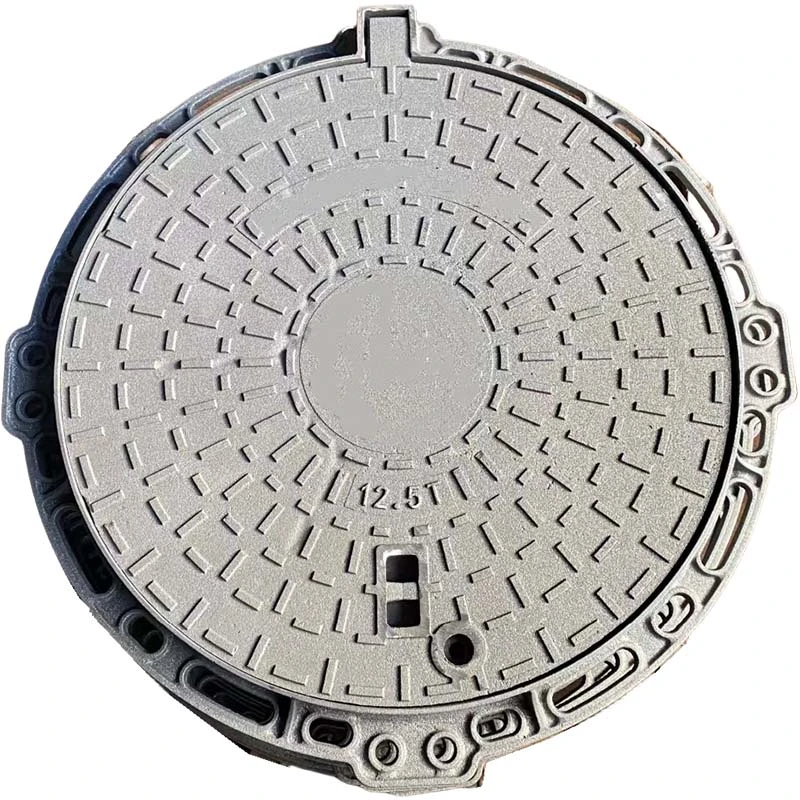

One of the primary advantages of ductile iron grating is its ability to support large amounts of weight while maintaining structural integrity. This quality is essential in environments such as roads, sidewalks, and industrial sites, where heavy vehicles or machinery frequently traverse. Ductile iron grating is designed to accommodate these loads without bending or breaking, ensuring safety and longevity. Furthermore, the smooth surface of the grating reduces the risk of accidents, as it provides excellent traction for pedestrians and vehicles alike.

Moreover, ductile iron grating is resistant to corrosion, a property that significantly extends its lifespan compared to alternative materials like steel. The protective coatings applied to ductile iron can further enhance resistance to environmental factors, such as moisture and chemicals, which are prevalent in industrial settings. As a result, ductile iron grating requires less maintenance over time, translating to lower operational costs for businesses and municipalities.

ductile iron grating

Another factor contributing to the popularity of ductile iron grating is its versatile design. Manufacturers can produce grating in various sizes and configurations, allowing for customization according to specific project requirements. This adaptability makes ductile iron grating suitable for diverse applications such as drainage covers, trench covers, and platform access. Additionally, the aesthetic appeal of ductile iron grating can complement urban landscapes, providing a balance between functionality and visual design.

Sustainability is also an essential consideration in today’s construction and infrastructure projects. Ductile iron can be recycled, meaning that end-of-life gratings can be repurposed without significantly impacting the environment. The production process of ductile iron is energy-efficient, and using recycled materials reduces the demand for virgin raw materials, lessening the overall carbon footprint associated with manufacturing.

As cities and industries continue to develop and expand, the demand for durable and reliable materials will only increase. Ductile iron grating stands out as a sustainable, efficient, and robust solution to meet these growing needs. Engineers and architects increasingly recognize the importance of selecting materials that not only serve their functional purposes but also contribute to sustainability goals.

In conclusion, ductile iron grating is an indispensable component of modern infrastructure due to its impressive mechanical properties, resistance to corrosion, and design versatility. By investing in ductile iron products, municipalities and industries can enhance the safety and longevity of their structures while also taking a step towards more sustainable construction practices. The future of infrastructure will undoubtedly benefit from the continued use of ductile iron grating, ensuring a more durable and resilient built environment.

-

The Essential Component for Safe Urban InfrastructureNewsMay.14,2025

-

The Backbone of Urban InfrastructureNewsMay.14,2025

-

Practical and Stylish Solutions for Your Drainage NeedsNewsMay.14,2025

-

Lamphole Frame and Cover: Essential for Urban InfrastructureNewsMay.14,2025

-

A Seamless and Aesthetic SolutionNewsMay.14,2025

-

A Must-Have for Safety and DurabilityNewsMay.14,2025

-

Pipe Repair Clamps: Your Ultimate Solution for Efficient RepairsNewsMay.09,2025