galvanized pipe clamp repair

Understanding Galvanized Pipe Clamp Repair

Galvanized pipe clamps are integral components in plumbing and HVAC systems, designed to secure and support pipes, preventing movement and potential damage. Over time, wear and tear can lead to the need for repairs or replacements of these clamps. Understanding how to repair galvanized pipe clamps can save homeowners both time and money.

The Importance of Pipe Clamps

Galvanized pipe clamps are made from steel coated with a layer of zinc to prevent rust and corrosion, which is especially vital in environments where moisture is prevalent. These clamps play a crucial role in maintaining the integrity of piping systems by holding pipes in place and providing structural support. Properly secured pipes can prevent leaks, structural damage, and costly repairs down the line.

Identifying Damage

Before attempting a repair, it's essential to identify the specific issue with the pipe clamp. Common problems include rusting, bending, or breakage. Inspect the clamp closely; if it's corroded or weakened but not broken, a repair may be sufficient. If the clamp is severely damaged or missing, replacement might be the better option.

Tools and Materials Needed

For a straightforward repair, you will typically need a few basic tools and materials

galvanized pipe clamp repair

1. Replacement Clamps If the existing clamp is beyond repair, having new galvanized pipe clamps on hand is essential. 2. Screws or Bolts Depending on the clamp type, you may need screws or bolts for secure attachment. 3. Wrench A wrench can help tighten or loosen bolts during the repair process. 4. Wire Brush For cleaning rust and debris off existing clamps before applying any sealant or paint.

Repair Process

1. Safety First Before beginning work, ensure the system is depressurized and, if applicable, drained. Wear gloves and goggles for protection. 2. Remove the Damaged Clamp Use a wrench to loosen the screws or bolts holding the clamp in place. Carefully detach the clamp from the pipe. 3. Clean the Surface If the clamp is rusted, use a wire brush to remove rust and debris. This will help in the application of rust-resistant paint if needed.

4. Inspect and Repair If the clamp is still usable, consider applying a rust-resistant sealant or paint for extra protection. If it’s too damaged, fit a new clamp in place.

5. Reattach the Clamp Position the clamp around the pipe and secure it with screws or bolts. Ensure it is tight but avoid over-tightening, which could damage the pipe or clamp.

6. Testing Once everything is reassembled, check for stability and ensure there are no leaks. Turn the system back on and observe for any issues.

Conclusion

Repairing galvanized pipe clamps may seem daunting, but it is a manageable task with the right tools and knowledge. Regular maintenance and timely repairs can prolong the life of your plumbing or HVAC systems, ensuring they function efficiently. Whether you choose to repair or replace your pipe clamps, understanding the importance of these components can lead to a more secure and reliable home infrastructure.

-

The Smarter Choice for Pedestrian AreasNewsJun.30,2025

-

The Gold Standard in Round Drain CoversNewsJun.30,2025

-

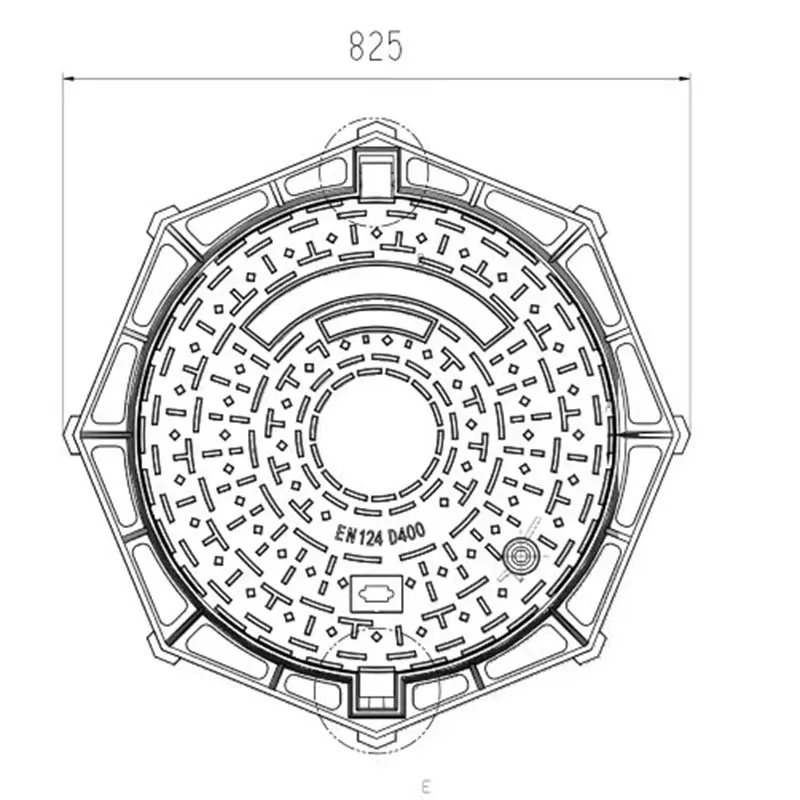

The Gold Standard in Manhole Cover SystemsNewsJun.30,2025

-

Superior Drainage Solutions with Premium Gully GratesNewsJun.30,2025

-

Superior Drainage Solutions for Global InfrastructureNewsJun.30,2025

-

Square Manhole Solutions for Modern InfrastructureNewsJun.30,2025

-

Premium Manhole Covers for Modern InfrastructureNewsJun.30,2025