Exploring the Importance and Function of Washers in Gate Valve Applications and Maintenance Procedures

Understanding Gate Valve Washers Essential Components for Efficient Operation

Gate valves are crucial elements in various industrial applications, including water supply, oil and gas, and chemical processing. They are designed to regulate fluid flow through a pipeline effectively. One of the essential components of a gate valve is the washer, which plays a vital role in ensuring the valve operates efficiently and reliably. This article will delve into the importance of gate valve washers, their materials, types, and maintenance practices to ensure long-lasting performance.

Importance of Gate Valve Washers

Gate valve washers serve several critical functions. Primarily, they provide a sealing surface that prevents leaks when the valve is in the closed position. A good quality washer ensures that the valve can maintain a tight seal, preventing the escape of fluids and conserving valuable resources. In addition to sealing, washers also minimize friction between the valve parts, facilitating smooth operation during opening and closing.

When a gate valve is actuated, the washer must withstand various forces, including pressure from the fluid flow and mechanical stress from the valve operation itself. Failure of the washer can lead to significant issues, including leaks, reduced flow control, and even complete valve failure. Therefore, selecting the right washer for a specific application is paramount to ensuring the overall performance and longevity of the gate valve.

Materials Used in Gate Valve Washers

The choice of material for gate valve washers is crucial, as it directly influences the performance and durability of the valve. Common materials used for washers include rubber, PTFE (Polytetrafluoroethylene), and various metals.

1. Rubber Washers Rubber is one of the most widely used materials for gate valve washers due to its excellent sealing properties and flexibility. However, rubber may degrade over time, especially when exposed to high temperatures or aggressive chemicals. It is essential to choose a rubber compound suited to the specific operating conditions.

2. PTFE Washers PTFE is known for its high chemical resistance and ability to withstand extreme temperatures. Washers made of PTFE are ideal for applications involving aggressive chemicals or high-temperature situations, making them a popular choice in many industries.

3. Metal Washers Metal washers, often made of stainless steel or bronze, provide durability and strength. They are typically used in high-pressure applications where rubber or PTFE might not suffice. Metal washers may be used in combination with rubber or PTFE to enhance sealing capabilities and reduce wear and tear.

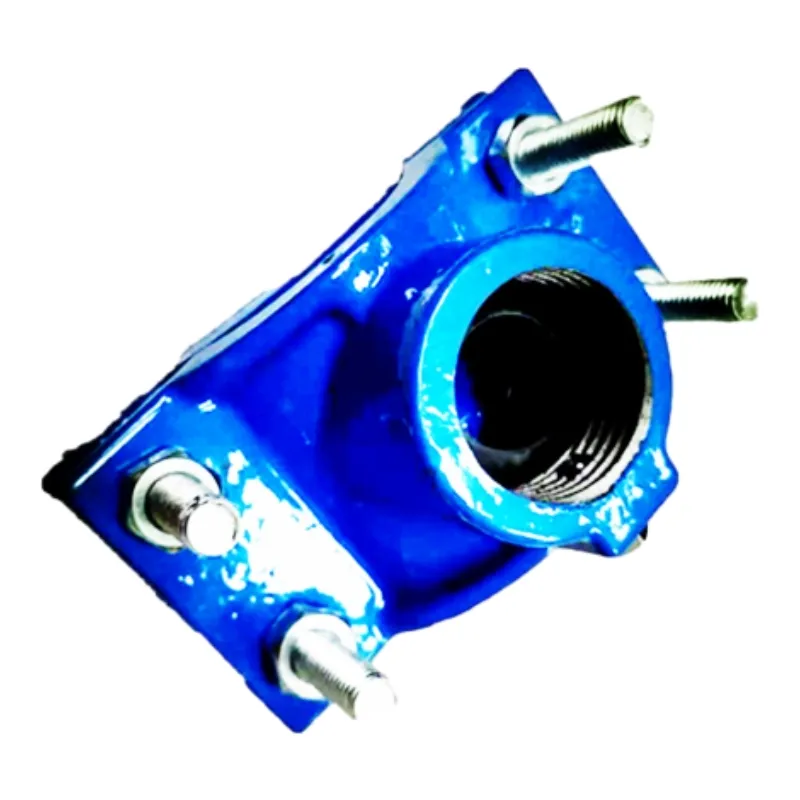

gate valve washer

Types of Gate Valve Washers

Gate valve washers come in various designs, each suited for specific applications. The most common types include flat washers, beveled washers, and composite washers.

- Flat Washers These are the simplest type and are widely used in standard applications. They provide a reliable seal and are easy to install.

- Beveled Washers These are designed to fit into specific grooves and provide a more effective seal in certain valve configurations.

- Composite Washers These are hybrid designs combining materials, such as a metal core with a rubber or PTFE outer layer, offering the benefits of both materials.

Maintenance of Gate Valve Washers

To ensure the longevity and efficiency of gate valve washers, routine maintenance is essential. Regular inspections should be conducted to check for signs of wear, cracking, or deformation. If a washer is found to be damaged, it should be replaced promptly to prevent leaks and operational issues.

Furthermore, operators should always follow the manufacturer's recommendations regarding the type of washer to use and the conditions under which the gate valve operates. Proper installation and regular maintenance will significantly reduce the risk of failures and extend the service life of the gate valve.

Conclusion

Gate valve washers are vital components that significantly affect the performance of gate valves. Understanding their function, material properties, and types is essential for ensuring the reliable operation of valves in various applications. Appropriate selection and regular maintenance of washers can lead to enhanced efficiency, reduced downtime, and greater overall system reliability. Whether in water treatment facilities, oil pipelines, or chemical processing plants, safeguarding the integrity of gate valve washers is crucial for optimal performance.

-

Square Sewer Cover Enhances Urban SafetyNewsAug.01,2025

-

Pipe Fitting Requires Precise AlignmentNewsAug.01,2025

-

Manhole Step Is DurableNewsAug.01,2025

-

Manhole Cover Is Found WorldwideNewsAug.01,2025

-

Hole Cover Frame On RoadsNewsAug.01,2025

-

Gully Grate Improves Road SafetyNewsAug.01,2025

-

Man Hole Cover Round Load CapacityNewsJul.31,2025