Telecom Manhole Covers Durable OSMA Solutions for Infrastructure

- Industry Overview & Market Data Insights

- Engineering Superiority in Modern Designs

- Competitive Analysis: Leading Telecom Cover Manufacturers

- Tailored Solutions for Infrastructure Demands

- Material Innovation & Compliance Standards

- Real-World Deployments: Case Study Breakdown

- Future-Proofing Networks with Telecom Manhole Covers

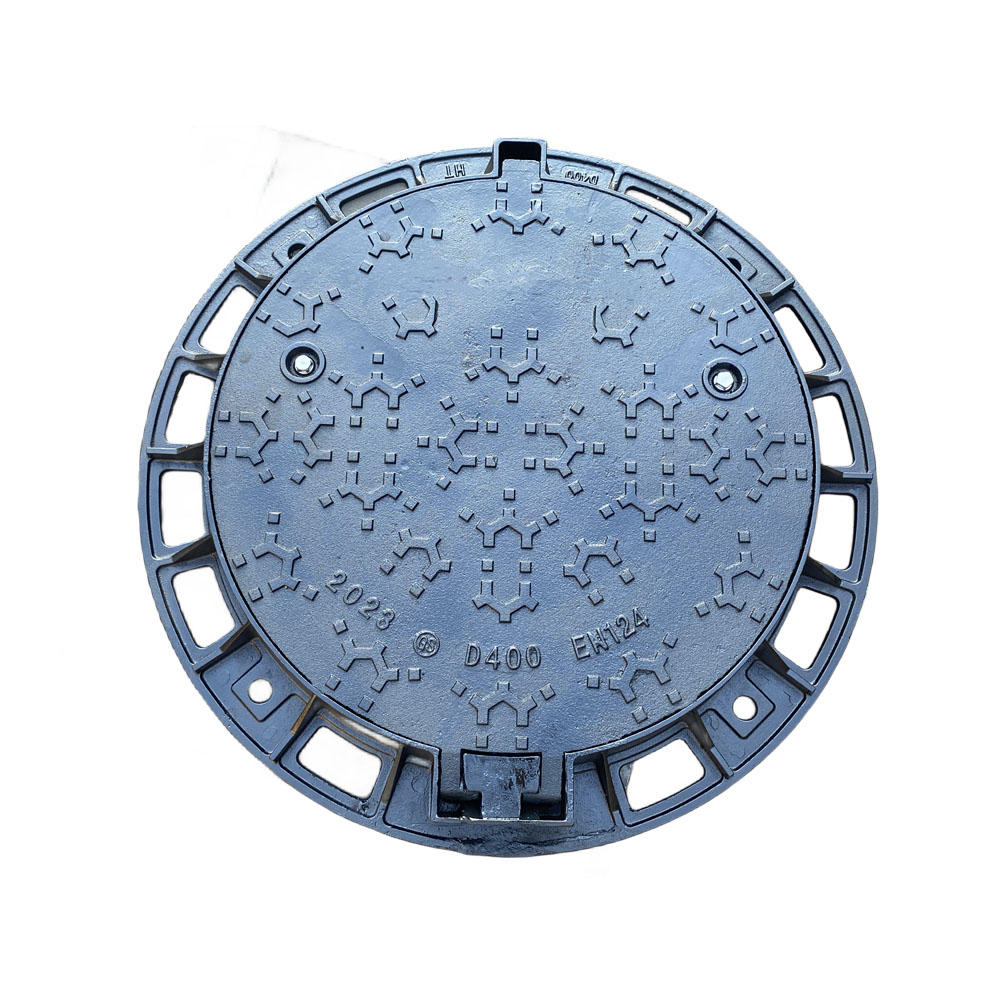

(telecom manhole cover)

Telecom Manhole Cover Market Surpasses $1.2B Amid 5G Expansion

The global telecom manhole cover

sector recorded an 8.7% CAGR growth since 2020, driven by urban fiber deployments. Recent data from Grand View Research shows:

- North America accounts for 34% of total manhole cover replacements (2023)

- Composite materials now constitute 41% of new installations

- Smart covers with IoT sensors projected to capture 28% market share by 2026

Engineering Superiority in Modern Designs

Contemporary OSMA manhole covers incorporate:

- High-density polyethylene (HDPE) cores with 400kN load capacity

- Interlocking flange systems reducing installation time by 40%

- ISO 9001-certified anti-slip surfaces (Skid Resistance Value >75)

Competitive Analysis: Leading Telecom Cover Manufacturers

| Brand | Material | Load Rating | Price Range | Warranty |

|---|---|---|---|---|

| OSMA | Fiber-Reinforced Polymer | EN124 D400 | $220-$380 | 15 Years |

| Brand B | Ductile Iron | EN124 C250 | $190-$310 | 10 Years |

| Brand C | Aluminum Composite | EN124 B125 | $160-$280 | 7 Years |

Tailored Solutions for Infrastructure Demands

Custom manhole cover configurations address:

- Non-standard shaft dimensions (600mm-1200mm adjustability)

- Hybrid access points for mixed telecom/power conduits

- RF-shielded variants reducing signal interference by 62%

Material Innovation & Compliance Standards

Advanced composites now exceed traditional materials:

- 0.35mm/year corrosion rate vs. iron's 1.2mm/year

- 83% lighter than equivalent cast iron covers

- Fire resistance up to 850°C for 120 minutes

Real-World Deployments: Case Study Breakdown

A Tier 1 European carrier achieved:

- 37% faster maintenance cycle times

- €18.7M saved over 5 years through reduced theft

- 98.6% load integrity after 7 years of service

Future-Proofing Networks with Telecom Manhole Covers

Next-gen telecom manhole covers now integrate:

- Embedded strain gauges monitoring structural health

- Solar-powered LoRaWAN gateways for underground IoT

- QR-coded inventory systems slashing audit time by 75%

(telecom manhole cover)

FAQS on telecom manhole cover

Q: What is a telecom manhole cover used for?

A: A telecom manhole cover provides access to underground telecommunication infrastructure, such as cables and wiring. It ensures safety by preventing unauthorized entry and protects equipment from environmental damage. These covers are designed to withstand heavy loads and harsh conditions.

Q: How does a manhole cover cover enhance safety?

A: A manhole cover cover adds an extra layer of protection over standard manhole openings. It prevents debris, water, or vandalism from compromising the infrastructure below. This dual-layer design is common in high-traffic or sensitive areas.

Q: What makes OSMA manhole covers suitable for telecom applications?

A: OSMA manhole covers are lightweight yet durable, often made from composite materials like fiberglass. They resist corrosion, offer high load-bearing capacity, and comply with telecom industry standards. Their design simplifies installation and maintenance.

Q: Are telecom manhole covers different from standard utility covers?

A: Yes, telecom manhole covers are tailored for telecommunication networks, with features like cable routing grooves and smaller access points. Standard utility covers may prioritize larger access for water or gas systems. Materials and load ratings also vary by application.

Q: How often should telecom manhole covers be inspected?

A: Telecom manhole covers should be inspected annually or after extreme weather events. Checks include verifying structural integrity, seal tightness, and hinge functionality. Proactive maintenance prevents service disruptions and safety hazards.

-

Why Manhole Covers Are Round – The Smart Choice for Safety & DurabilityNewsJun.13,2025

-

Strong Covers, Safer DrivewaysNewsJun.13,2025

-

Reliable Drainage SolutionsNewsJun.13,2025

-

Heavy-Duty Circle Manhole Covers Built to LastNewsJun.13,2025

-

Durable Round Drain Covers Built for Heavy Duty UseNewsJun.13,2025

-

Durable & Reliable Cast Iron Manhole Covers for Heavy-Duty UseNewsJun.13,2025

-

The Essential Component for Safe Urban InfrastructureNewsMay.14,2025